Aug . 18, 2025 11:28 Back to list

Why Steel Grating Is Dominating Industrial Flooring and Safety Applications

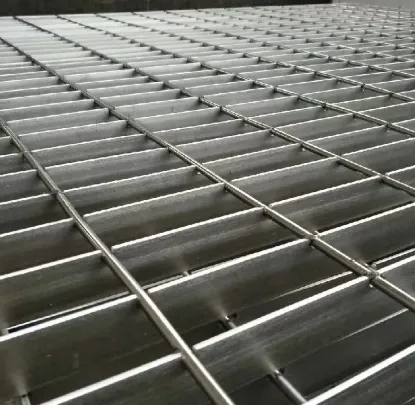

With the increasing demand for high-strength, durable, and safe flooring in industrial environments, steel grating has rapidly become the top choice for platforms, walkways, and stair treads across many sectors. Whether it’s in a factory, refinery, or large warehouse, steel grating systems offer unmatched reliability and versatility.

The Versatility of Steel Grating in Stair and Platform Construction

One of the most prominent applications of steel grating is in industrial staircases and elevated platforms. Its open-grid design ensures efficient drainage and airflow, reducing the risk of fluid accumulation and corrosion. This makes steel grating for sale a superior option over solid plates, particularly in outdoor and chemical-exposed environments. Unlike perforated or profiled plates that may trap debris or water, steel grating provides a clear, self-cleaning path that maintains traction even in wet conditions.

On platforms and mezzanines, the load-bearing capacity of steel grating ensures safety even under heavy foot and machinery traffic. Its modularity also allows for quick installation, minimal maintenance, and seamless integration into pre-existing structural systems, making it a favorite among construction engineers and plant managers alike.

Types of Steel Grating and Their Structural Advantages

There are several types of steel grating, each with unique characteristics tailored to specific applications. Welded bar grating, the most common type, is formed by welding perpendicular bearing bars and crossbars, offering excellent strength and load distribution. Press-locked grating is assembled by hydraulically pressing cross bars into slotted bearing bars, providing a cleaner look while maintaining rigidity. For environments requiring higher corrosion resistance, swage-locked or stainless steel grating is often recommended.

Additionally, custom spacing in the bearing bars allows manufacturers to meet different slip resistance requirements and load-bearing needs. Clients exploring steel grating for sale often compare these types to select the best option for their operational demands. At the same time, reputable steel grating company catalogs provide thorough guidance and testing data to simplify this decision-making process.

Steel Grating vs. Perforated and Profiled Plates: A Material Comparison

While perforated and profiled metal plates are used in similar applications, their structural behavior and safety performance differ significantly. Perforated plates offer decorative and acoustic advantages but lack the drainage and strength of steel grating. Profiled plates, with their rigid, patterned surface, may provide limited grip, but they fall short in applications demanding structural support and maximum airflow.

The three-dimensional layout of steel grating ensures superior grip and anti-slip performance, which is critical in heavy-duty and hazardous work zones. Safety grating walkway systems, specifically engineered for high-traffic areas, surpass traditional plates in minimizing slips and ensuring long-term performance. This is especially beneficial in petrochemical, marine, and mining industries where worker safety is paramount.

Anti-Slip Treatments and Safety Innovations in Steel Grating

Slipping accidents remain a major concern in industrial environments, which is why anti-slip treatments for steel grating are vital. Manufacturers often offer serrated bearing bars that enhance grip by creating additional friction points. This serration is particularly valuable for safety grating walkway installations in icy or oily conditions. Another method is applying epoxy or anti-slip coating to the grating surface to improve traction.

Drainage slots and angled bearing bar designs further optimize water shedding and reduce hydroplaning risks. The inclusion of abrasive grit finishes or rubber inserts for walkways exposed to high foot traffic or aggressive conditions adds an extra layer of protection. These advancements make steel grating a forward-thinking choice not just for durability but also for prioritizing employee wellbeing.

Steel Grating FAQs

What are the main differences between steel grating and perforated plates?

Steel grating has an open-grid design that offers excellent drainage, ventilation, and load-bearing strength, making it ideal for heavy-duty platforms and walkways. Perforated plates, on the other hand, are better suited for aesthetic or acoustic applications and typically offer lower structural capacity.

Which types of steel grating are most commonly used?

The most common types of steel grating include welded bar grating, press-locked grating, and swage-locked grating. Welded grating is widely used for its strength and durability, while press-locked offers a cleaner appearance and is often chosen for architectural or light-duty applications.

How is anti-slip performance improved in steel grating?

Anti-slip performance is enhanced through serrated bearing bars, epoxy coatings, abrasive grit layers, and rubber inserts. These features make steel grating particularly effective for safety grating walkway systems in hazardous or wet environments.

Can steel grating be used for residential projects?

While steel grating is more common in industrial and commercial settings, it can also be used in residential projects like outdoor decks, drains, and garden walkways, where drainage and strength are important.

What factors influence steel grating price?

Steel grating price varies based on type (welded, press-locked, etc.), material (carbon steel or stainless steel), load requirements, surface treatment, and quantity. Customization and additional safety features may also affect the overall cost.

-

What is NATO Wire

NewsAug.18,2025

-

Why the Right PVC Horse Fence Matters More Than You Think

NewsAug.18,2025

-

Why Reno Mattress Is Revolutionizing Slope Protection and Civil Engineering

NewsAug.18,2025

-

Why Reinforcing Trench Mesh Is the Backbone of Durable Foundations

NewsAug.18,2025

-

Why Galvanized Welded Wire Mesh Is the Backbone of Modern Construction

NewsAug.18,2025

products.